Raw Material Preparation Section

The raw materials of autoclaved aerated concrete are mainly calcareous materials containing calcium oxide (lime/cement), siliceous materials containing silica (fly ash, sand, tailings, other solid wastes, etc.), aluminum powder paste and other additives. Generally, the sand needs to be processed by ball mill, made into slurry. The prepared slurry is stored in the mixing tank. Continuous mixing is required to prevent slurry deposition and ensure stable concentration for easy batching.

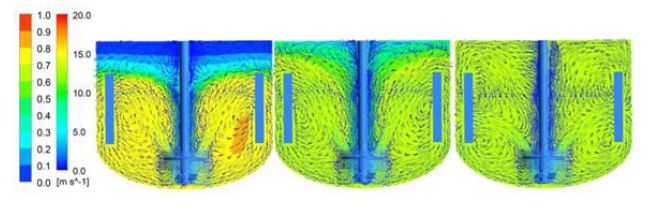

The full mixing of slurry plays an important role in ensuring the process quality of products. Our patented design of double-layer cross blade and modular guide cylinder can ensure the mixing effect with lower energy consumption, which is good for producing AAC of different densities from 250kg/ m³ to 700kg/ m³.

- Lower Energy Consumption High Mixing Efficiency

- Stable Process Quality

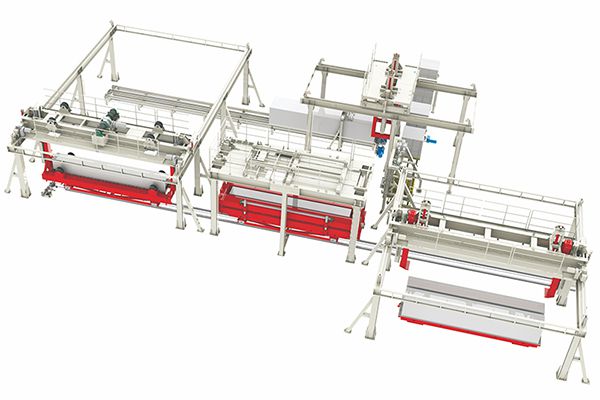

The pouring device outlet can be automatically lowered into the mould for pouring, and the height of the outlet can be automatically adjusted with the change of slurry flow and the mould slurry level which can effectively reduce the splash of the slurry and the cluster of large pores. The outlet is specially designed to cushion the huge flow pressure, which can effectively avoid flushing the mould oil layer away.

- Lifting Type Discharge Avoid Big Bubble

- Avoid Flushing Oil Away