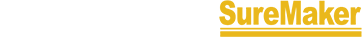

Pre-curing & Cutting System

After pouring, the mould with slurry is transported to the pre-curing room, where chemical reaction of the slurry results in rising and formation of porous green cake in the mould. Then the green cake will be cut to the required dimensions of products and the six sides of the cake will be cut to smooth surface by the cutting system. The waste materials cut from the green cake can be directly dropped into the waste pit and recycled use by the waste recycling system. The panel grove is also processed before autoclaving so that the waste materials can be directly recycled which can avoid much solid dry waste and saving energy comparing with the post processing of panel groove.

- The lifting adopts hydraulic lifting and gear rack forced mechanical synchronization, which is stable and reliable, with high synchronization and good safety.

- After being driven by motor & reducer, the walking of demoulding machine is guided by gear rack and combined with dynamic detection of precision detection encoder to ensure accurate walking positioning, stable and reliable operation.

- The mould opening and closing device adopts the hydraulic linear pushing mode to open and close the mould.

- The walking wheel and vehicle body are connected by end face flange, which is convenient for maintenance.

Fine bread head scraper, oblique knife rough scraping &straight knife fine scraping to ensure the smooth surface of the green cake. Smart grooving cutters changing system can change cutters automatically to meet different cutting requirements of panel grooving sizes.

Cutters Can Be Changed Automatically

Horizontal Cutting Machine

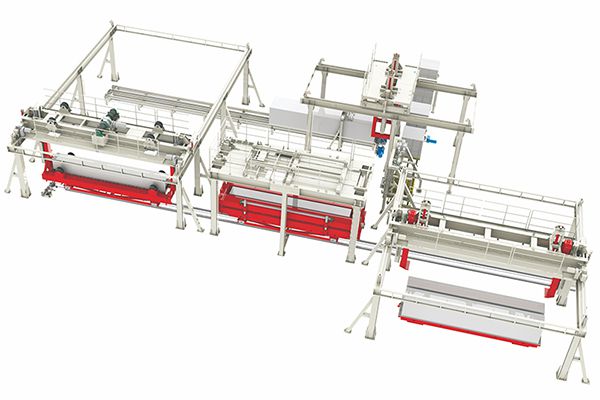

In order to solve the problem of settlement crack. we have developed the cable staved beam horizontal cutting machine. Multiple pairs of wire hanging columns are set on the inclined beam, and only one steel wire is hung on each pair of wire hanging columns. With the special design. the settlement crack or tai collapse can be avoided Each hanging wire post can be adjusted, which is more conducive to ensure the cutting accuracy.

- Patented Design

- Super Smooth & Thin Panel Cutting

- Multiple Pairs of Independent Hanging Wire Posts

- No Settlement Crack or Collapse

Vertical Cutting Machine

The swing frame of vertical cutting machine equipped with guide rail slider can swing with low frequency and large amplitude so as to ensure the swing accuracy and make the cutting surface more smoothly. The mechanical synchronous lifting frame structure ensures the stability of green cake lifting without shaking.

In the new generation design scheme the green cake lifting device can be set under the ground to simplify the structure of the vertical cutting machine, optimize the space and the automatic steel wire replacement device can be an option.

Air tilting machine can turn the vertically placed green cake in to horizontally placed one, and remove the upper and bottom waste layers. These waste materials can directly fall into the waste slurry pit and to be recycled more easily reducing the cost and pollution of post autoclave processing. The design of machine will reduce the civil construction cost and difficulty.

- Patented Design

- Easy Construction & Low Cost

- Keep Clean & Efficient

(Only for Flat Autoclaving Production Process)

The green cake smart separating machine can separate panels of different specifications intelligently which is suggested for the flat cake autoclaving production process technology to producing high precision AAC panels.