With rich experience from hundreds of successful projects, we are committed to building AAC plants with the development concepts of reducing carbon footprint, environmental protection and intelligence, leading and promoting the development of the industry.

- Customized: The AAC plant will be customized to our customers’ specific requirements, all the relevant factors and conditions, such as available space, production capacity, climate, packing, logistic, budget, and much more will be taken into account.

- Intelligence: intelligent data, interconnection, environmental detection.

- Flexible: The production capacity and product specifications are flexible, which can meet the demands of different customers.

- Energy saving: Zero system waste, low energy requirements and minimal consumption of raw materials. Meet the requirements of reduce carbon footprint and sustainable development.

- Durable: High quality material, craftsmanship and whole-hearted service ensure the long-term, efficient and stable operation of the AAC factory.

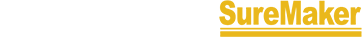

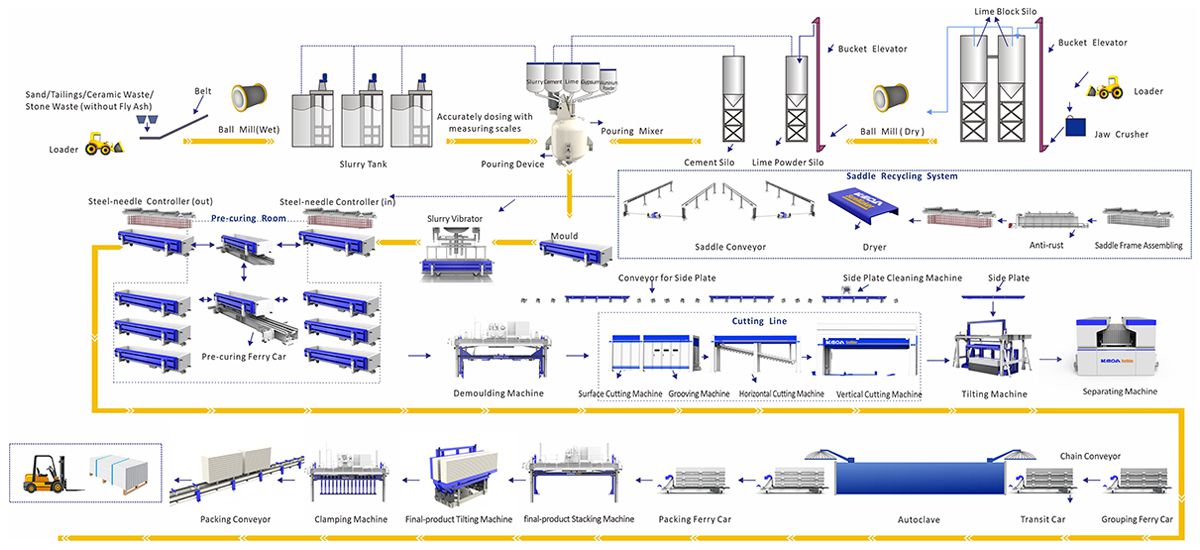

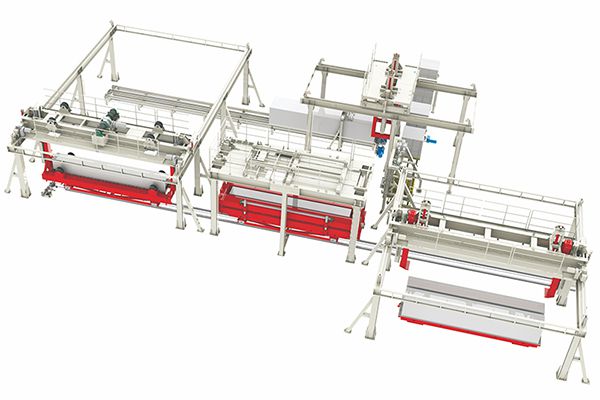

The AAC production technology of KEDA SUREMAKER is based on years of successful experience and innovations. To ensure the highest-precision cutting of AAC block/panel, the cake is cut in an upright position in our plants. On this basis, we offer two production technology concepts with vertical cake autoclaving and flat cake autoclaving.

The plant design is compact and convenient for the product sorting and packaging. It is the classic design of layout planning.

The flat cake autoclaving is recommended for producing AAC panel, and the green cake separation or the white cake separation can be options.

According to our design concept, the cake is cut in an upright position which ensures perfect cutting precision and grooving of the cake before autoclaving. Our design is flexible and customized according to the specific needs of customers. Single head autoclave or double head autoclave can be options according to your needs.

Market Research

- Project feasibility study

- Environmental markeng evaluation

- Investment Scope Overview

Raw Material Investigation

- Raw material analysis

- Formula customization

- Utilization of solid wastes

Customized design

- Capacity Design

- Equipment Scope Design

Equipment manufacturing&Commissioning

- Equipment manufacturing

- Ex-factory Commissioning

AAC Plant Construction

- AAC Plant Engineering

- Project Installation Supervision

- Project commissioning

Service&Support

- Personnel Training&Local/Remote Service & Documentation/Software

- Market Development & Product Applications Consulting

- Accessories Database & Production Technology Upgrading

- Production Management Support

- Raw Material Chemistry Analysis & Formula Design Production Technical

- Process Research & New Product Development Research

- Equipment Scope Design & Investment Scope Overview

- AAC Plant Engineering & Ex-factory Commissioning

- Project Installation Supervision

- Project commissioning

- Personnel Training & Local/Remote Service & Documentation/ Software

- Market Development & Product Applications Consulting

- Accessories Database & Production Technology Upgrading

- Production Management Support

| Solution Series | Output/300 Days (m³/year) | Suggested Land Area (㎡) |

| KS | 100,000-150,000 | 15,000-20,000 |

| KS.Plus | 150,000-200,000 | 20,000-25,000 |

| KS.Max | 200,000-250,000 | 25,000-30,000 |

| KS.Pro Max | 300,000-600,000 | 30,000-40,000 |

We have different cake size production line designs, including but not limited to, 4.2m* 1.2m* 0.6m, 4.8m*1.2m* 0.6m, 5m* 1.2m* 0.6m, 5.2m* 1.2m* 0.6m, 5.4m* 1.2m* 0.6m, 6m* 1.2m* 0.6m, 6m* 1.5m* 0.6m, etc. Further more, our engineers will provide customized plant solutions depending entirely on all the relevant factors and conditions, such as available space, production capacity, climate, packing, logistic, budget, and much more.