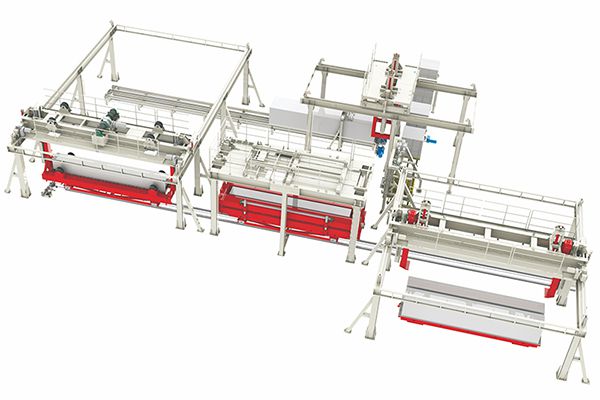

Autoclaving Section

After cutting, the green cakes are grouped before autoclave, and then sent to autoclave for autoclaving with high temperature (200 ℃) and high pressure (1.2MPa). The autoclaving time is about 10~12 hours. The steam in the autoclave can be reversed to each other to realize recycling and save energy consumption.

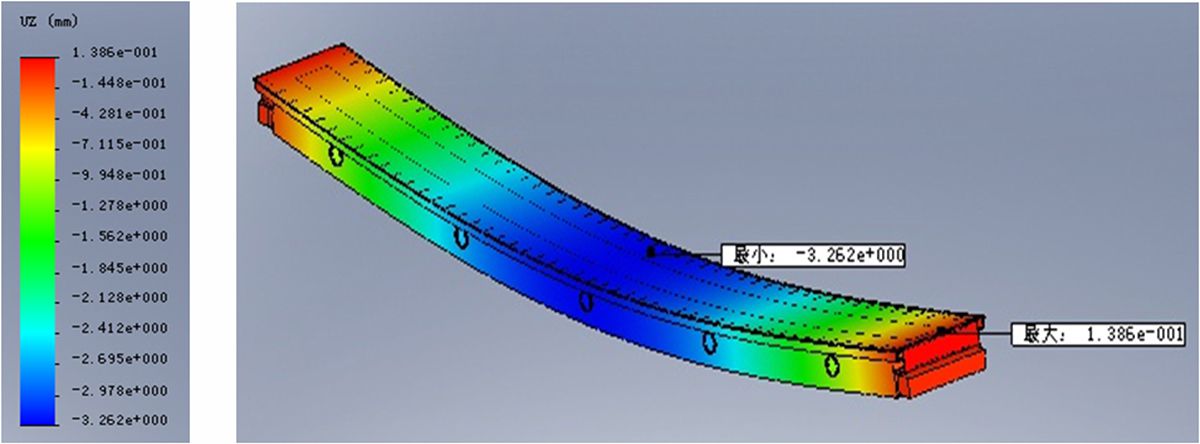

The patented design of the side plate has been analyzed by finite element method. The load deformation of the plane on the side plate is less than 1/100the rigidity is good. The side plate is processed as a whole and the processing error does not exceed± 1mmso that it can be perfectly combined with the mould without slurry leakage. The high quality of the side plate can ensure stability and accuracy during cutting.

- Patented Design& Finite Element Analysis

- Good Rigidity, Stability& Durability

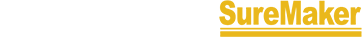

- Integral Processing Technology