The automation research center provides customers with all-round comprehensive services, including full life cycle project services, knowledge discussion and training related to the electrical control and operation of autoclaved aerated concrete production line, intelligent technology research and development, upgrading and application testing.

Project life cycle services

- According to the needs of the project - establish an exclusive team for the project

- Customized electrical scheme drawing design Initial funding to the Design Institute / electrical schematic drawings / electrical layout design of the whole line

- Installation, commissioning and production guidance of on-site electrical hardware

- Standardized software program debugging to achieve rapid production

- Centralized laboratory training, base training, on-site operation training and teaching auxiliary materials, answering questions and solving doubts

- Remote service, data monitoring and management

Electrical training base

- Staff internal training seminar

- Customer and industry training classes

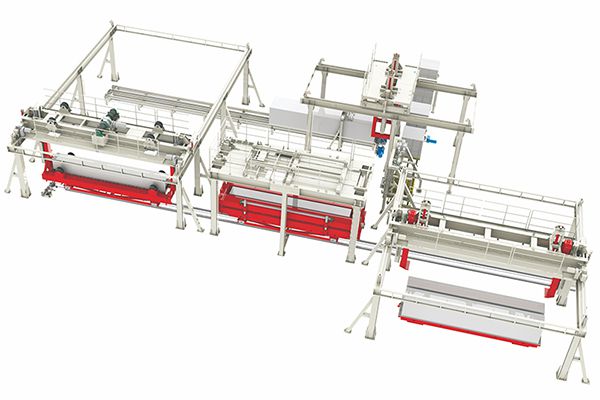

Intelligent technology of AAC production line

- Intelligent storage system

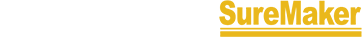

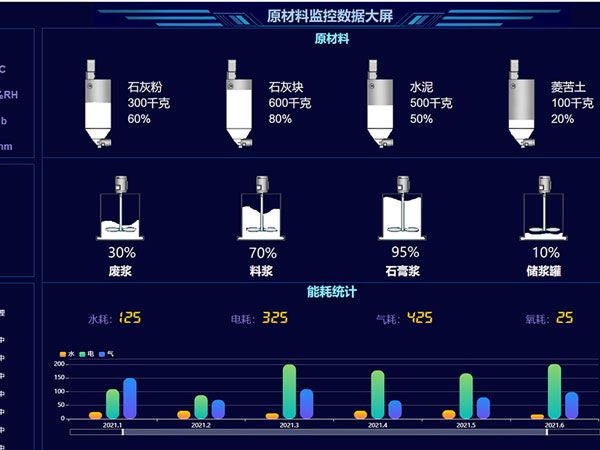

- Energy management system

- Equipment status monitoring

- Alarm and fault management system

- Order management and monitoring

- Reporting system

- Personnel management

- Flexible formula management

- Remote maintenance

Data management of electrical control

- Recipe data

Raw material consumption monitoring / automatic calculation and formula management - Data monitoring & alarm and fault elimination

Sensor data monitoring / valve switching status / instrument data monitoring / electric energy monitoring / motor temperature, vibration data / network status, abnormal condition monitoring / fault operation or operation instructions do not meet production conditions, alarm and record - Visual centralized management of factory -- factory role and management authority

- RFID data - track the production process and automatically adjust the transmission instructions Smart factory, standardized process setting, intelligent operation control of each production section It can master the production progress at any time, record the process data in the production process, automatically convey the work instructions of each section according to the order requirements, and intelligently adjust the work parameters; When the fault occurs, the production process data can be traced to investigate the cause.

Advantages of frequency converter communication control mode

- Screw conveyor, cutting machine, walking crane, cutting conveyor car and ferry car all adopt frequency converter communication control mode, which makes the control more gentle and stable, and saves energy and electricity.

- With high control accuracy, it can extract the current, temperature, alarm, fault, energy and other state information of the motor, and provide real-time and accurate data for the overall equipment management, energy management and fault alarm management of the equipment

- Convenient for data collection and remote maintenance

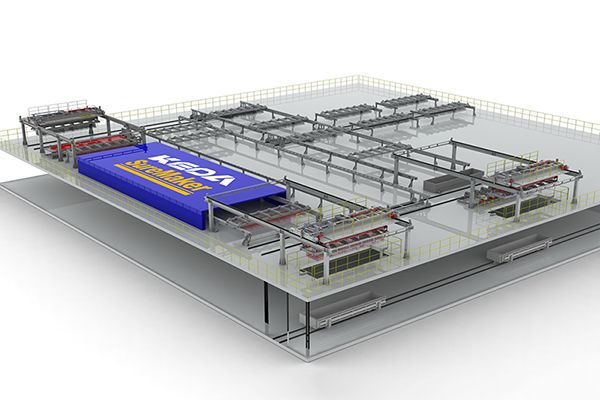

KEDA SUREMAKER (Anhui KEDA Industrial Co. Ltd), the leading AAC plant solution supplier from China, is committed to providing holistic AAC plant solutions including plant and formula design, manufacturing, installation, training, operation and application consulting, etc. The company has its own independent national postdoctoral research stations and technology research centres and has edited 5 China national standards and 12 industry standards.