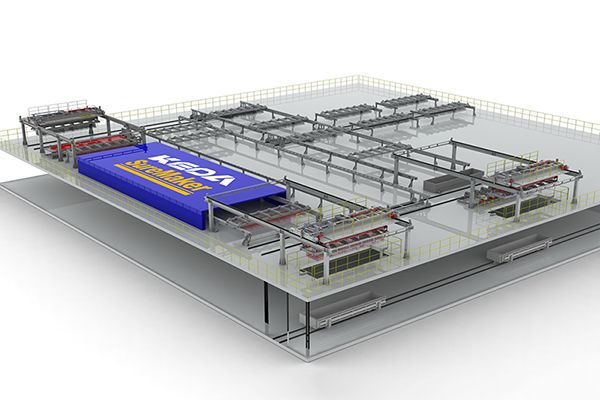

Fully Automatic AAC Packing Section

Automatic AAC packing system can realize the packing with pallet or without pallet. The pallet specification can be 1.2mx 0.6m, 1.2mx 1m ,1.2mx 1.2m, 1mx 0.6m, the height of stacking can be 1.2m, 1.5m, 1.8m and 2.4m.

The clamping machine can walk smoothly and accurately to the specific position. It equipped with 15 pairs of collects with independent ball valves which is convenient for transporting the blocks and panels produced by the same mould to different conveyor chains.

When the collects are released the products can be transported to the next station immediately through the conveyor which greatly saves the operation time.

According to our design concept the cake is cut in an upright position which ensures perfect cutting precision and grooving of the cake before autoclaving. Our design is flexible and customized according to the specific needs of customers. Single head autoclave or double head autoclave can be options according to your needs.

- Fully Automatic AAC Packing Section

- Sort Panels & Blocks of One Cake

- High Operation Efficiency

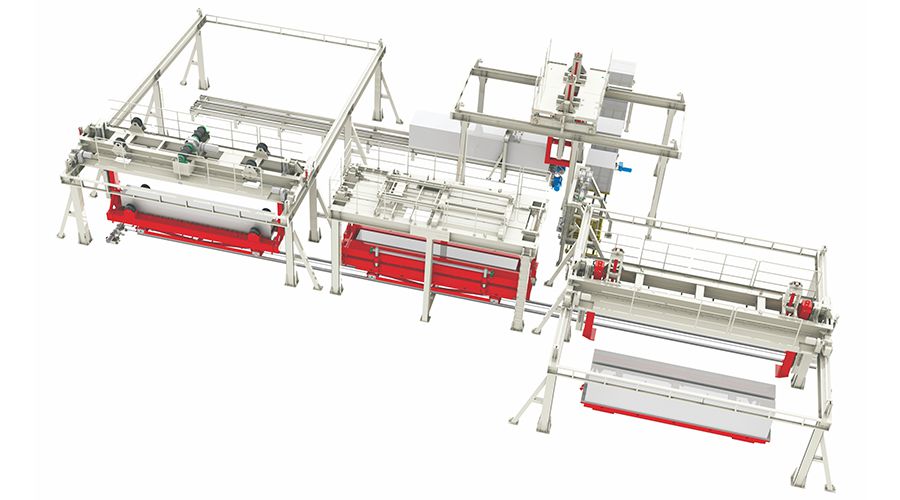

White Cake Separating Machine

White cake separating machine adopts the fixed separating frame with cake lifting device. With the upgraded structure design, we can ensure the smooth running and durability of action precision.

- The cake transfer machine is driven by servo motor and gear rack walk to ensure fast movement and accurate positioning;

- The clamping device adopts hydraulic clamping, and the clamping force can be adjusted to avoid damaging the white cake;

- The lifting is controlled by hydraulic oil cylinder and guided by slide rail, with stable and reliable action.