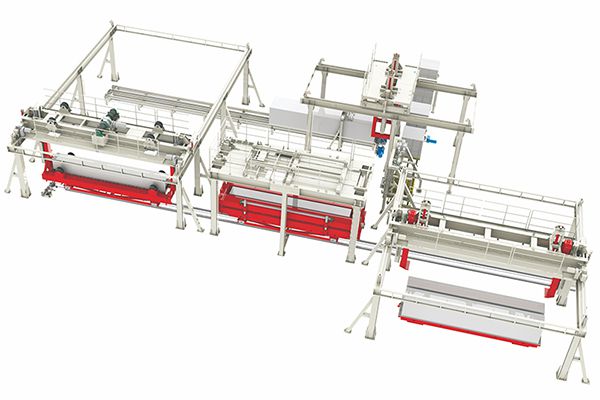

Automatic Reinforcement Saddle Frame Cycle System

(Panel Production)

The automatic reinforcement saddle frame cycle system consists of a needle holder, needle cleaner, wax dipping tank, automatic saddle frame conveyor, mesh cage assembly conveyor, electric saddle frame transport platform, anti-corrosion section crane, anti-corrosion tank, dryer conveyor chain, drying box, inserting crane, and the like. The automatic reinforcement saddle frame cycle system can ensure the efficiency of steel mesh cage assembly and recycling work. So as to improve the production efficiency of the whole plant.

The saddle frame with the needles attached is lifted. This causes the needles to be pulled out of the green cake. The needle reception machine moves the needle frame to the needle cleaner unit and then to the wax dipping tank. The automatic saddle conveyor transfers the saddle frame with the needles to the mesh cage assembly conveyor where meshes are fixed to the saddle frame. Then the saddle frame containing the mesh cages is transported to the anti-corrosion section crane which conveys it to the anti-corrosion tank.

After the anti-corrosion process, the saddle frame containing the mesh cages is hoisted on a dryer conveyor chain ending up in the drying box, where the cages are dried. After drying, the cages are transferred to the inserting crane to wait for their introduction into the AAC slurry. After the mesh cages have been inserted, the mould is conveyed by a transport platform to the pre-curing chamber. The needles are pulled out of the green cake after pre-curing, and subsequently the saddle frame with the needles attached proceeds to the next cycle.

The wax dipping, anti-corrosion and drying sections are integrated into the saddle frame cycle process, thus reducing ineffective material consumption, saving space and labour costs for these sections, and improving the efficiency of mesh cage assembly and recycling work.