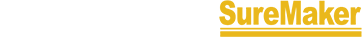

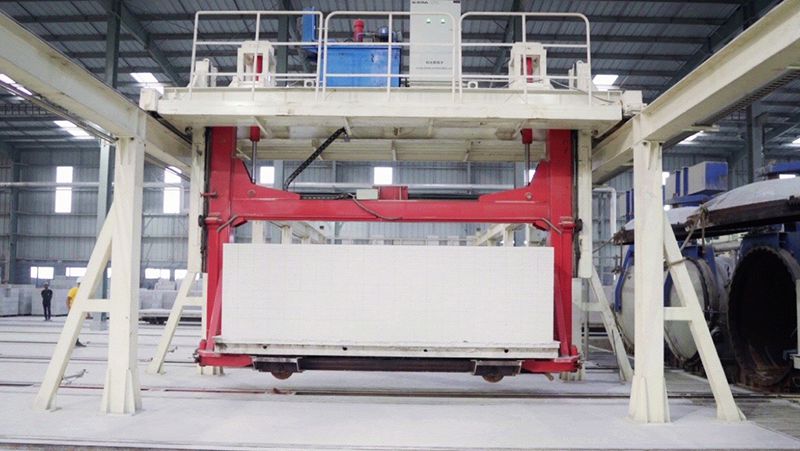

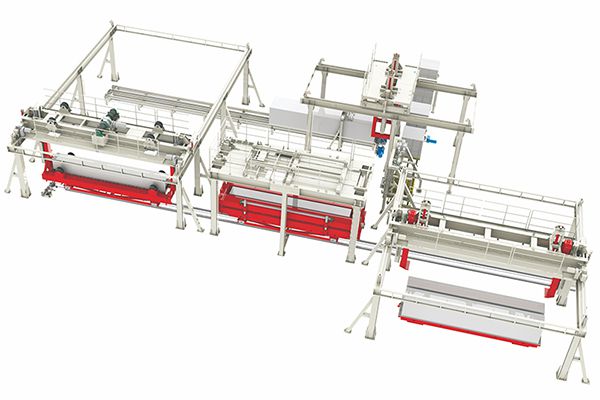

As a leading autoclaved aerated concrete plant solution supplier in China, Keda Suremaker advocates provid- ing holistic AAC plant solutions with regards to raw material analysis, plant planning, R&D, manufacturing, construction guidance, production management, training, and marketing. In addition to high-quality equip- ment, achieving excellent performance of AAC products requires experience in the production processes and mature quality control procedures.

In recent years, India has become a new land of opportunity, with population and economic growth contributing to the continued rapid development of the country’s construction industry. The Indian econ- omy is highly dependent on infrastructure and var- ious government policies. With the national govern- ment’s continued focus on green building materials, the market for AAC blocks is simultaneously expand- ing. The quantities of raw materials used in AAC con- struction are only about one-third of the quantities used for other building materials.

In addition, most government departments and construction compa- nies are now moving towards AAC as their preferred building material because it offers many additional advantages, such as resistance against fire, insects and earthquakes, as well as sound insulation, which makes this technology the most convenient and cost-effective solution in the construction process. Since traditional red clay bricks are a major cause of air pollution and soil degradation, the government has continuously been working at reducing their use. All these factors promote the production of AAC blocks in India.