China’s ceramic manufacturing industry has experienced a period of stable development. Output figures of ceramic products and the number of enterprises doing their business in the ceramic industry have grown tremendously. Today, China is the largest worldwide producer and exporter of ceramics boasting a rapid development in this industry. The result is a vast amount of ceramic powder wastes on account of trimming and polishing processes during the production of ceramic walls. According to some statistics, more than 20 million tons of ceramic waste is annually produced by ceramic production facilities. In the past, there have not been any relevant recycling technologies; ceramic waste was regarded by companies as “garbage” used for landfills or to fill gullies, roadbeds and the like.

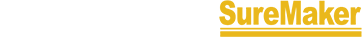

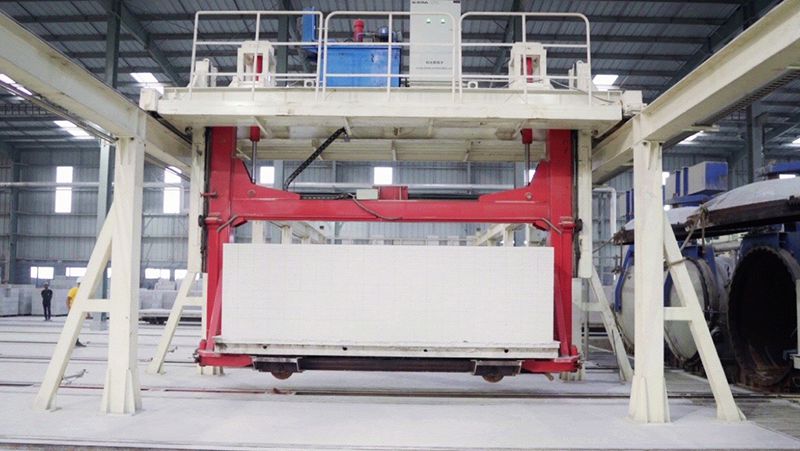

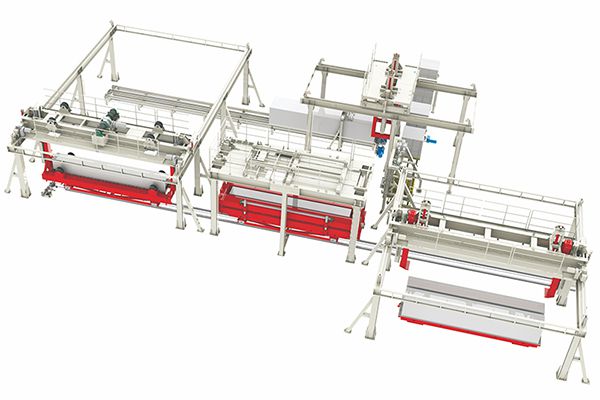

Environmental problems of this nature were an extremely unpleasant phenomenon in the Shangdong Province as well. Challenged by the Chinese government, the ceramic industry of this province attempted to find ways in solving this environmental pollution problem especially caused by the long-term storage of ceramic polishing powder wastes. It was therefore in 2014 that a company located in the Shandong Province, Heyue Technology, started to cooperate with Keda Suremaker to installan AAC plant with an annual capacity of 300,000 m³. This facility has since been using ceramic polishing powder waste as the main raw material for the production of AAC panels and blocks.