How to ensure the equipment quality

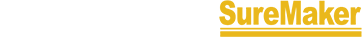

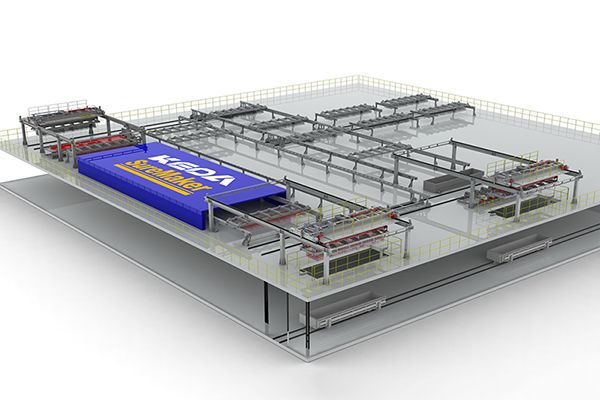

Manufacture Center

The production and manufacturing base has blanking workshop, welding workshop, machining workshop, CNC machining center workshop, painting workshop, assembly workshop, finished product warehouse, electrical workshop and new product R&D and testing center. Introduce advanced equipment, such as gantry flame cutting machine, plasma cutting machine, large bending and forming equipment, Panasonic industrial robot, Panasonic carbon dioxide digital welding machine, Lincoln submerged arc welding, spectrum analyzer, X-ray flaw detection, C-type supporting double station automatic robot welding system, well annealing and quenching and tempering furnace heat treatment equipment, large-scale automatic shot blasting and spraying production line, 14m CNC boring and milling machine, 8m CNC gantry boring and milling machining center, 4m CNC boring and milling machining center, TK6920 large floor boring, small giant vertical and horizontal machining center, five axis machining center, engraving machine, 260t large lifting equipment, etc., with the processing and manufacturing capacity of 50 AAC production lines per year.

The manufacturing engineer team covers welding, machining, numerical control, testing and other professional fields, with 83 welding related project qualifications. The product production progress and quality can be effectively controlled in the process of processing and manufacturing with SAP integrated system, MES workshop management system, SCM supply chain management system, OA automation office system and other advanced production information management systems, covering planning, production scheduling, material distribution, inspection and confirmation, office etc.

- QC by Standards We have established hundreds standards of process, operation and inspection to control product quality. Passed ISO9001 quality management system certification and European CE certification.

- QC by Detection Testing Perfect measuring tool management system, equipped with dynamic balance tester, ultrasonic flaw detector, vibration tester, laser rangefinder, digital level meter, sound level meter, infrared thermometer and other precision electronic measuring equipment. Use precision testing instruments and equipment to test and control product quality.

- QC by Ex-factory Commissioning After assembly of each equipment, the electrical and hydraulic commissioning must be carried out before shipping to the plant to ensure the best performance.

- QC by Informatization With the ERP system, MES system and PDM system, we strengthen the quality management process, transparency of product quality information and long-term trace ability of quality results.

- QC by Responsibility The quality control system which combining self-inspection and special inspection of the installation process is strongly implemented, and the quality assessment of each installation-related party is clearly defined. The results of the inspection and evaluation of onsite ancillary products commissioning will form the basis for our evaluation of suppliers.